Sustainability is woven into the very fabric of our mission to “craft every meter of cable with excellence.” For us, excellence means delivering superior performance while actively protecting our environment and communities. Our commitment to eco-friendly cable manufacturing is a long-term strategy focused on three pillars: designing greener products, implementing cleaner production processes, and fostering a circular economy. We believe that providing sustainable wire and cable solutions is not just an option but our responsibility as a leading manufacturer in the global market.

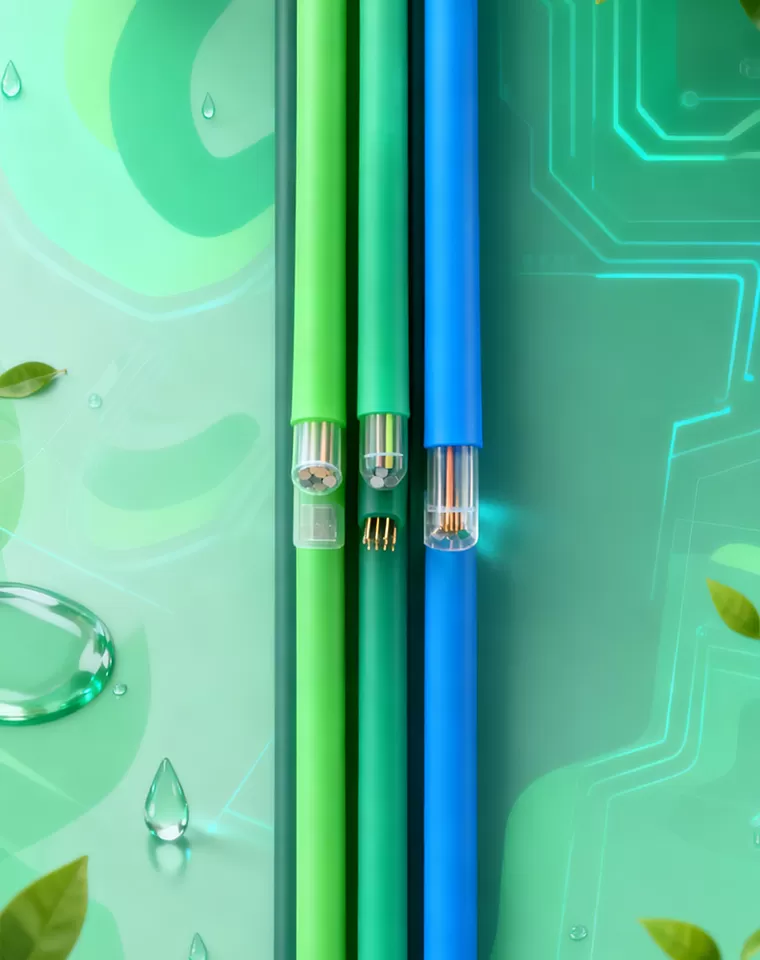

The journey towards environmental responsibility in the cable industry begins at the design stage. We are committed to innovating our products to reduce their environmental impact across their entire lifecycle.

All our cables are strictly compliant with RoHS (Restriction of Hazardous Substances) and REACH regulations, ensuring they are free from lead, mercury, and other harmful materials, safeguarding both the environment and end-users.

We champion the production and use of our LSZH cables. In the event of a fire, these cables emit very little smoke and no toxic halogen gases, significantly improving safety for people and infrastructure. This is a critical green cable solution for public spaces like airports, subways, and data centers.

We actively explore the use of recycled materials in our jackets and insulations and continuously work on designs that minimize material usage without compromising performance, reducing resource consumption and waste.

Our dedication to sustainable cable production is reflected in our manufacturing operations. We are on a continuous path to reduce our energy consumption and environmental footprint.

We have implemented energy-efficient technologies and practices in our factories, including optimizing production lines to reduce power consumption and investing in high-efficiency machinery.

Our manufacturing processes adhere to strict internal environmental standards that often exceed local regulations. We have advanced systems in place to treat and manage industrial wastewater and air emissions, minimizing our impact on the local ecosystem.

We are committed to a “zero waste to landfill” goal where feasible. Production scrap, such as copper and plastic, is systematically segregated and sent to certified recycling partners, closing the loop in our production cycle.

We recognize that true sustainability extends beyond the factory gate. We are actively working to promote a circular economy for cables by focusing on the end-of-life stage of our products.

Our cables are designed with recyclability in mind. We prioritize the use of mono-materials or easily separable materials to facilitate efficient recycling processes.

We are exploring and developing partnerships with specialized recycling entities to establish effective take-back and recycling programs for end-of-life cables, ensuring they are processed responsibly and do not end up in landfills.